The Game-Changing Role Of AI in Supply Chain

Artificial Intelligence

Let’s start this blog by learning about some of the popular Fortune 500 companies that have successfully implemented and reaped benefits from AI implementation in the Supply chain.

Fortune 500 companies that have implemented AI in Supply Chain Management

Amazon:

“I kind of like to think about AI as like oxygen,” he said. “You don’t feel it, you don’t see it. It’s what makes the magic happen.”- Scot Hamilton, Amazon’s Vice President.

The biggest eCommerce fleet, Amazon is known for its sophisticated AI implementation in the supply chain. However, what comes as a surprise is, that Amazon has been using AI for more than 25 years now! How?

The integrated AI algorithm manages inventory, forecasts the demand, and optimizes the logistics. The AI integration has helped the team speed up supply chain operations by almost 75%.

To meet the daily demand of more than 400 million products, Amazon uses AI to foresee things ahead of time. It has also invested in a new robotic system like Sequoia that assists in increasing store inventory operations by 75%.

There is much more to the benefits that Amazon managed to grab, and you can read more about it here.

Ford:

Ford, one of the biggest automobile companies, has used AI + Machines Learning in multiple ways.

For example, it uses AI to detect wrinkles in the car seat;

Ford, also uses an AI-driven platform called CarStory to understand the inventory data for used cars;

It uses simulation technology, NVIDIA DGX-1 artificial intelligence supercomputer to gauge the car’s performance before it hits the track.

Given the clear evidence of technology, it is only imperative for supply chain businesses to implement AI in the Supply chain to speed up decision-making, reduce cycle times, speed up multiple operations, and pave the way toward continuous improvement.

What is AI in Supply Chain Management?

Once, overlooked and now very high in demand, “Supply Chain Management” was a term coined in the 1980s. However, it was only after the COVID-19 pandemic, that people started recognizing the significance. The prolonged shortages of various products, and personal protective equipment, led manufacturers to think of more effective ways to manage such situations. And hence, businesses turned to AI to manage their supply chains.

Artificial Intelligence in the Supply Chain refers to the process of using AI tools and other AI-driven technologies to operate, manage, and oversee business operations.

The technology integration can go beyond the traditional software operations and benefit businesses in several ways.

For example, it helps in forecasting customer demand, discovering behavior patterns, making market predictions, and a lot many other things.

Do you agree that the introduction of chatbots takes the entire shopping experience to another level?

It is important to notice how embracing AI is preparing the supply chain fleet for future demands.

Fill out the form to learn more about AI implementation in Supply Chain

Learn More:- How AI in eCommerce Transforms the Shopping Experience?

How does AI in supply chain management work?

AI implementation in the supply chain streamlines various operations. Let’s dive deeper into how this works.

Optimizes logistics networks: In traditional shipping, the manufacturing partner takes care of the shipment and tracking, but this process can be time-consuming and prone to errors if the shipment status isn’t updated or monitored as per the timeline.

However, implementing AI in supply chain management optimizes the logistics operations right from the warehouse to distribution channels.

Furthermore, AI’s assistance in demand planning helps in predicting demand and assessing warehouse capacity based on this analysis.

AI when combined with IoT, makes businesses capable of achieving things next level.

AI in supply chain management also enables inventory tracking and market trends analysis. Artificial Intelligence enhances transparency within the supply chain system. This enhancement saves a lot of time and offers cost-saving operations.

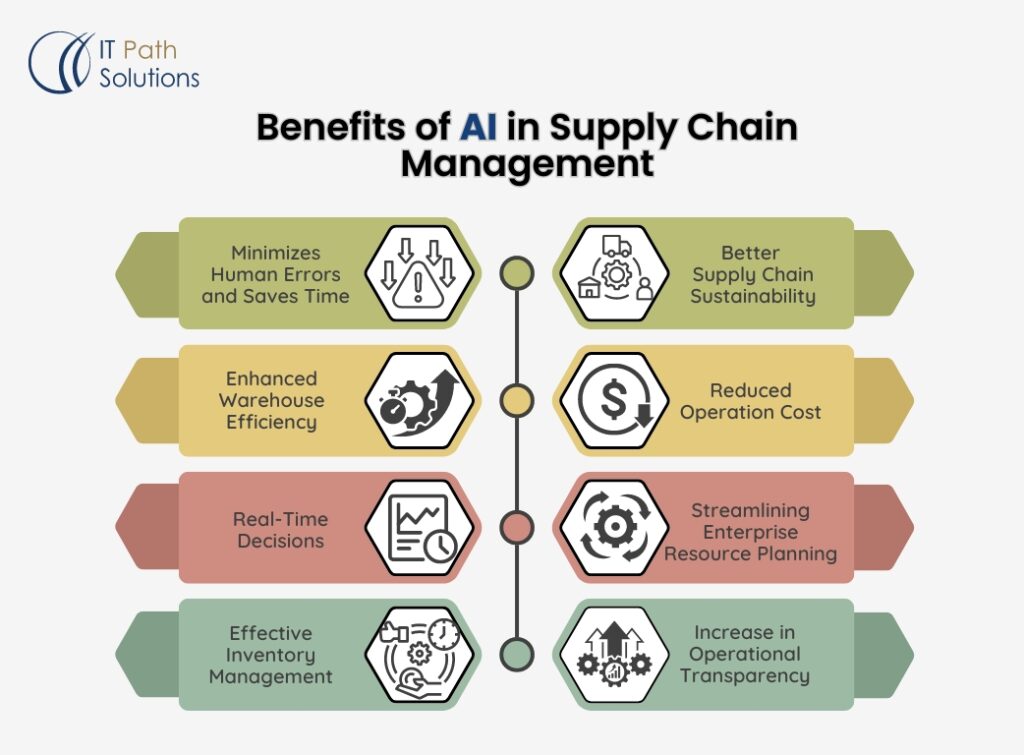

What are the benefits of AI in Supply Chain Management?

Early adopters of AI-enabled supply chain management have reduced logistics costs by 15 percent, improved inventory levels by 35 percent, and enhanced service levels by 65 percent.

AI in Supply Chain Management will take care of the ins and outs of the warehouse. From the receipt of the raw material in the warehouse to its distribution, shipment, and marketing, everything can be tracked with AI.

Intelligent data tools can effectively process a pool of data and fetch valuable insights that can drive proven results.

Some more advanced AI systems also enable the prediction of new consumer habits and anticipate future demands.

Let us discuss the benefits of AI in Supply Chain Management in depth:

Minimizes human errors and saves time:

AI can be trained to identify errors and product defects (remember, Ford using it to detect wrinkles in the car seats). This enables the supply chain team to anticipate human errors in advance and thus prevent major mishaps.

Enhanced warehouse efficiency:

The ahead-of-time functioning of AI tools assists in the timely retrieval of an item in the warehouse. AI-integrated systems operate more efficiently and accurately by simplifying a lot of manual tasks and speeding up the process.

Real-time decisions:

AI’s ability to break down complex data structures into simple language helps in reducing repetitive tasks. This enables effective inventory tracking and management while lowering operating costs.

Effective inventory management:

AI can be trained to follow the First-in-First-out rule to track the inventory effectively. It lets the manufacturer know the high demand for a particular product and ensures its supply accordingly. This assists in improving decision-making and improves supply chain forecasting.

Better supply chain sustainability:

By implementing predictive analytics in AI, manufacturers can predict the timelines of the shipment, manage its delivery routes, and thus save time and resources involved in managing it.

Reduced operation cost:

AI in supply chain management automates most of the processes, allowing the system to operate long hours as compared to human-managed operations. The AI robots work faster, and error-free, increasing the level of productivity.

The entire AI-operated cycle reduces the overall cost of operation, thereby benefiting the businesses.

According to McKinsey, 61% of manufacturing executives report decreased costs, and 53% report increased revenues as a direct result of introducing AI in the supply chain.

Streamlining Enterprise Resource Planning:

Supply chain management often involves AI in procurement and purchases from around the globe. This might bring complexity while handling the process. However, AI in the supply chain will streamline the process and make systems future-ready.

The easy setup of connecting people, and purchases will make things more data-driven.

Increase in operational transparency:

Figuring out who did what might be a problem when such a huge system is operating. AI in supply chain management will virtually bring everything under one roof allowing the business owner to see operations end-to-end. Business owners can now identify the weak performing areas and plan improvement strategies accordingly.

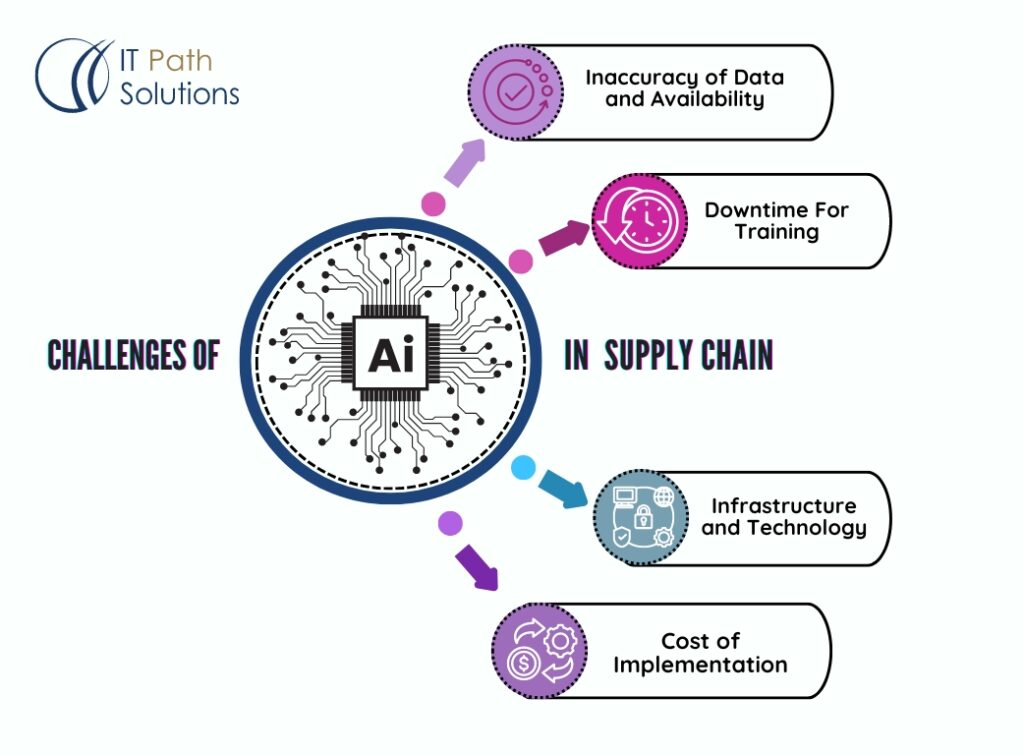

Challenges of AI in Supply Chain:

AI implementation in the Supply Chain is appealing, but businesses should also understand the risks involved. The below-mentioned are some common challenges involved in AI implementation.

Inaccuracy of data and availability:

AI algorithms are capable of generating accurate results from the data resources that are fed. However, if the origin of the data is inaccurate or poorly designed, the result won’t be as incompetent or low quality.

In such cases, human intervention would be needed to ensure that whatever is fed to the AI algorithm is accurate and aligned.

Downtime for training:

Extensive training will be required for those involved in AI implementation. This training can be time-consuming and may disrupt operational schedules. Professionals should be prepared for potential downtime during this period and have their plans ready.

Infrastructure and technology:

The entire supply chain system must be ready for AI implementation. Challenges such as outdated systems, platform incompatibility, and insufficient infrastructure may arise.

However. to address these issues, conduct a comprehensive audit of the infrastructure, identify gaps in the system, and seek appropriate solutions. Alternatively, you can seek the help of IT companies specializing in AI.

Cost of implementation:

Many Machine Learning models are expensive. A few you can buy pre-built, and others you need to build from scratch. This incurs a huge cost for businesses planning to implement AI in the supply chain.

Businesses need to analyze if they are ready to afford that cost of implementation.

Read More:- The Role of AI In Inventory Management

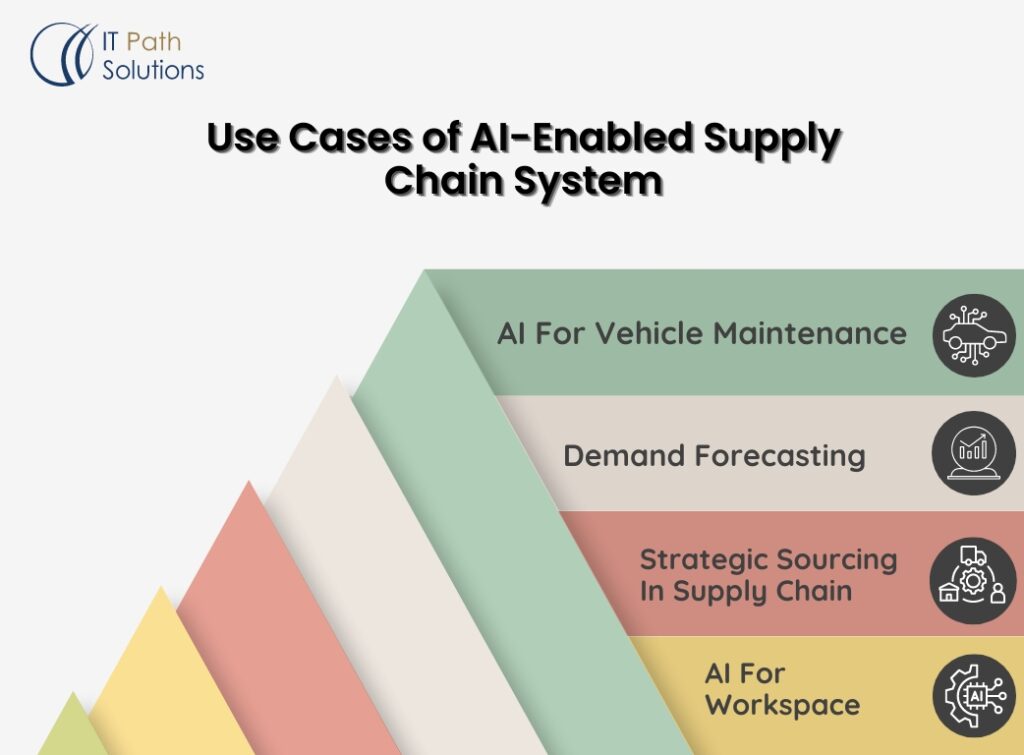

Use Cases of AI-enabled Supply Chain System:

To implement AI in supply chain management, it is important to where and how you will use AI automation. Here are a few typical use cases that you can implement for automation.

AI for vehicle maintenance recommendation:

IoT provides real-time updates on in-transit vehicles. Additionally, Machine Learning algorithms, using historical data, predict vehicle maintenance needs and potential failures. These algorithms can anticipate malfunctions in advance and alert you to take timely action.

Demand Forecasting:

AI in demand forecasting assists businesses in demand forecasting. The combination of Data Science + AI enables warehouses to identify products that are high in demand and manage the inventory accordingly.

Strategic Sourcing in Supply Chain:

The implementation will assist in identifying critical suppliers and partners. Businesses can pick up the best-valued and high-quality supplier and keep track of their product performance.

The predictive analysis helps you in compliance, and standardization of the sourcing activity.

AI for making manufacturing workspace safer for employees:

Computer vision powered by predictive analysis helps shape the safety of the employees working in the warehouse. AI analyses the space and the risk involved in the operation and directly reflects them on the screen.

Future of AI in Supply Chain Management in Brief:

As you can read, AI opens up endless possibilities for businesses operating in the supply chain. Here is the synopsis of how the future of AI in the supply chain will look like.

- More accurate and detailed forecast demands;

- Improved operations and optimized inventory levels;

- Faster delivery and enhanced safety measures

- Reduced operational costs and dependencies.

According to PwC, AI applications have the power to transform the way business is done and contribute up to $15.7 trillion to the global economy by 2030.

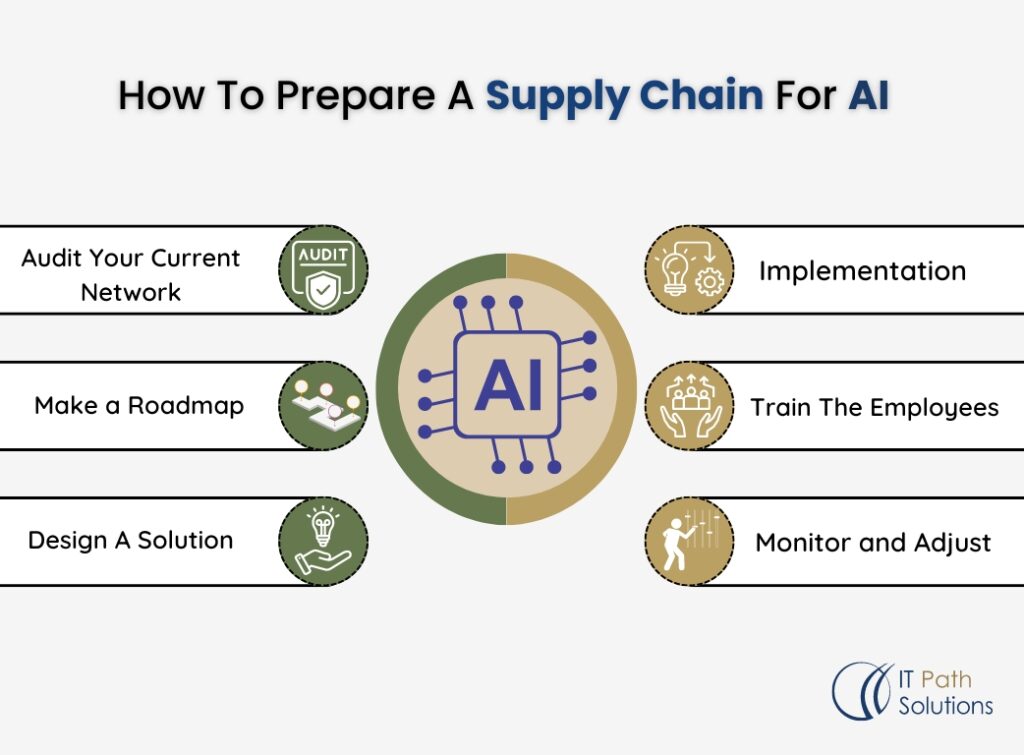

How to prepare a supply chain for AI?

You might find AI implementation in the Supply chain challenging, however, with the right vendor and a supporting partner, you can get everything managed effectively. Here are the steps to follow for systematic AI implementation.

Audit your current network

Business owners need to conduct a thorough analysis of the current setup and identify the pain points and productivity drains. This helps in planning things better and making the most of it.

Make a Roadmap

Right execution is the key! Before jumping onto the bandwagon, you must identify areas where AI implementation will make the most impact. Create a roadmap suggesting step-by-step transformation. This will help you in deciding your priorities for implementation.

Design a Solution

There are several solutions to choose from such as cloud-based applications, edge servers, data science platforms, and internet-connected devices. The selection depends upon your business-specific needs.

At this stage, you should consider involving an AI development company aka your vendor that can help you integrate the technology into your existing system.

Implementation

It is time to execute the steps working closely with the execution team and the management team. The implementation may cause downtime for a brief period, but you should prepare your employees for that.

Train the employees

It is important to bring everybody to the table. Just like you prepared yourself for the AI implementation, it is evident that you need to prepare your employees for the seismic change in operations with AI implementation. This will align their thoughts with the company’s objectives regards AI implementation.

Monitor and Adjust

AI is a constantly evolving field, and if you are implementing AI in supply chain management, it is important to monitor and make necessary adjustments. This will help in refining your process and the overall performance.

Is AI the future of the Supply Chain?

AI is unique and relatively new. However, its adoption will bring a definite improvement in supply chain planning, management, and operations.

Hence, if you feel that your existing supply chain needs an uplift, it is time to opt for our AI-integration services. We dig deep into the intricacies and help you find a scalable AI solution for your business.

Healthcare

Healthcare  Education

Education  Real Estate

Real Estate  Logistic

Logistic  Fitness

Fitness  Tourism

Tourism  Travel

Travel  Banking

Banking  Media

Media  E-commerce

E-commerce